540L Tank Clean Car Radiator Industrial Ultrasonic Cleaner & Cleaning Equipment

1-2 Set

$7,200.00

≥ 3 Set

$7,100.00

- Item No.20200925f20daMOQ1 Set

Choice

Quantity:

If you have your own design, please contact us, there will have a professional customer service to communicate with you.

Don't have your files right now?No worries, Check out our art tips for more information.

If over 500pcs, mass production will start until pre-production sample has been approved.

Est. 7 days production

Clean Car Radiator Industrial Ultrasonic Cleaner & Cleaning Equipment 540 litre tank

Ultrasonic Frequency Choices

Ultrasonic operating frequency is perhaps the single most important consideration when choosing an ultrasonic cleaning system. Each frequency has its own unique characteristics. Low frequencies are used for large, un-detailed parts with heavy contamination and produce un-even cleaning action in the fluid, while higher frequencies produce more evenly distributed cleaning action, and have the ability to penetrate small blind holes,

threaded areas, and other detail. More frequency choices 68kHz / 80kHz / 120kHz are available.

Choosing an ultrasonic frequency for a magnetostrictive system is easy, since there really is no choice at all. Magnetostrictive system designs typically operate at frequencies below 30kHz, making these systems unsuitable for most ultrasonic cleaning applications. Most parts being cleaned ultrasonically require the removal of lightly-bonded contaminants on the surface of precision parts, applications which are addressed

with 40kHz, 80kHz orCROSSFIRE Multiple Frequency Ultrasonics operating in this range. Low frequencies would produce in-consistent cleaning results on such parts, and parts may be damaged by cavitational erosion. Although Zenith manufactures 28kHz ultrasonic systems, they are rarely recommended for any ultrasonic cleaning applications, unless they are combined with 40kHz in a CROSSFIRE system. This is the direct result of the thousands of sample parts which have been test-cleaned ultrasonically at Zenith. Our Ultrasonic Testing Service is used to develop complete processes for our potential customers. Parts are submitted and tested in various ultrasonic frequencies and cleaning agents to determine the best process to use for a given application. Low frequency ultrasonic cleaning systems in the 25kHz-30kHz range never produce a better cleaning result than higher frequency systems do. In fact, it is exactly the opposite. Parts are cleaned more effectively in systems operating at 40kHz and above. Since these systems are less damaging to components, quieter in operation, and better at cleaning in fine detailed areas, these systems are usually recommended for any cleaning application.

Competitive Advantage:

- Material : SUS304/316L with 2mm thickness

- 15 years experience engineer will design the machine for you

- Filtration System: for heavy duty oil removing, cycle cleaning solvent, prevent second polution and better cleaning effects.

- PCB Board: manufactured by Skymen factory, more stable

Skymen JP Series:

Skymen | JP-1030 | JP-1036 | JP-1060 | JP-1072 | JP-1108 | JP-1144 | ||||

TANK | 500x406x500 | 500x460x550 | 700x650x650 | 1000x600x600 | 1000x900x600 | 1200x1000x800 | ||||

OVERALL | 680x586x850 | 680x640x900 | 900x850x1000 | 1200x800x950 | 1240x1140x950 | 1440x1240x1150 | ||||

MAX. CAPACITY | 101L | 126L | 295L | 360L | 540L | 960L | ||||

CONSTRUCTION | SUS 304 (MIRROR SHINING IMAGE AVAILABLE) | |||||||||

CONSTRUCTION | SUS 304 / 316L | |||||||||

ULTRASONIC POWER(MAX.) | 1500W | 1800W | 3000W | 3600W | 5400W | 7200W | ||||

ULTRASONIC | 28kHz/40kHz/68kHz/80kHz/120kHz | |||||||||

MAX. HEATING | 20~80C ADJUSTABLE | |||||||||

HEATING POWER | 3KW | 4.5KW | 6KW | 9KW | 12KW | 24KW | ||||

TIMER | 0~30min adjustable | |||||||||

DRAIN | ¾" VALVE | |||||||||

LID & BASKET | TAKE-OFF / STRUT LID; SUS 304 | |||||||||

CLEANING TANK’S | AC220V/380V/415V/440V. 3 | |||||||||

GENERATOR’S | AC110V/ 220V / 240V, 1 | |||||||||

GENERATOR | WITH SWEEP MODE AND REMOTE CONTROL | |||||||||

FEATURES | MULTI-DIRECTION CASTORS WITH BRAKE; | |||||||||

Optional | FILTRATION SYSTEM (PUMP, SUS FILTER, | |||||||||

Skymen 540L industrial ultrasonic cleaner as high quality Ultrasonic cleaning machine

Industrial High Sonic Power Ultrasonic Cleaning Machine

JP series single tank ultrasonic cleaner equipment system includes replaceable transducer box and generator. The transducer box and generator can be both build-in or separate but work together to operate ultrasonic cleaning process with transducer box immersible mounted in fluid tank, one side or both side or bottom mounted inside the tank. The number and placement of transducers is selected to give maximum results in any parts cleaning tank with any cleaning load. Specification of tank dimension and transducer boxes are custom made available. Either for mould of parts cleaning can receive perfect cleaning efficiency. Stainless steel basket is optional.

Application of Ultrasonic Immersible Transducer

immersible ultrasonic transducers This series of products is suitable to cleaning work pieces of various industries;such as plating components cleaning before plating,electronic,hardware machinery parts,clock and watch parts,semiconductor sillcon chips,glass vessels,bijouterie,spectacle frame, etc.

·Pre-plating cleaning for parts to be plated, oil and dirt removing for metal mechanical. Parts, cleaning semi-conductor Si-chips, spectacle frames and glass vessels.

·Lens, sunglasses, short-sighted mirror and prism, the microscope, camera, glass equipment, etc.

•electroplating accessories, watch & clock accessories, metal accessories, terylene filter core, semiconductor silicon, tools, lens, spectacle frames, jewelry and glass containers...etc.

Skymen 3 stage unit (multi-tank) ultrasonic cleaner machine

Industry | Cleaning objects |

jewelry | Jewelry, diamond, gold, silver products, |

machinery | Moulds, precision parts, pressing parts, camera parts, bearing, hardware tools |

electronics | PCB board, electronic parts, TV parts, computer parts |

Auto industry | engine parts, gear box, shock absorber, auto nozzle, cylinder, valve |

Dental& Medical | dental tools, medical tools, injector, surgery tools, dropper, glass container |

Plating& painting | polishing parts, SUS cutter, tableware, plating |

Food industry | Oven tray, boiler, bottles, bottle cap, filters |

Optical& watch maker | optical lens, eyeglass, sunglass, metal, gold, jewelry, diamond, watch band, watch cover, watch hand |

textile | spinneret plate, rubber parts, plastic molds, toy |

others | seal, flapper, coins, pottery, bank card, IGBT |

Why Choose ultrasonic cleaner?

Ultrasonic cleaner cleaning has been proven to be the most efficient method of removing contaminants, such as grease, oil, wax, fluxes, fingerprints, oxides and other deposits-from visible and invisible surfaces, holes and cracks. In general, if an item can be cleaned with liquid, it can be cleaned much faster and more thoroughly with an ultrasonic cleaner. In fact, it may not be possible to clean certain intricate and complex parts without the use of an ultrasonic cleaner.

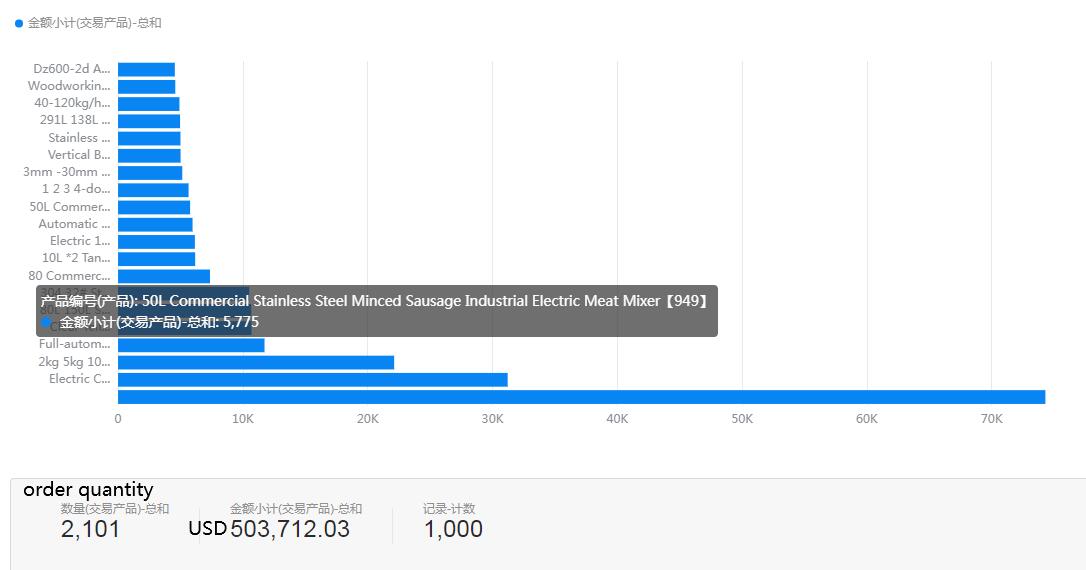

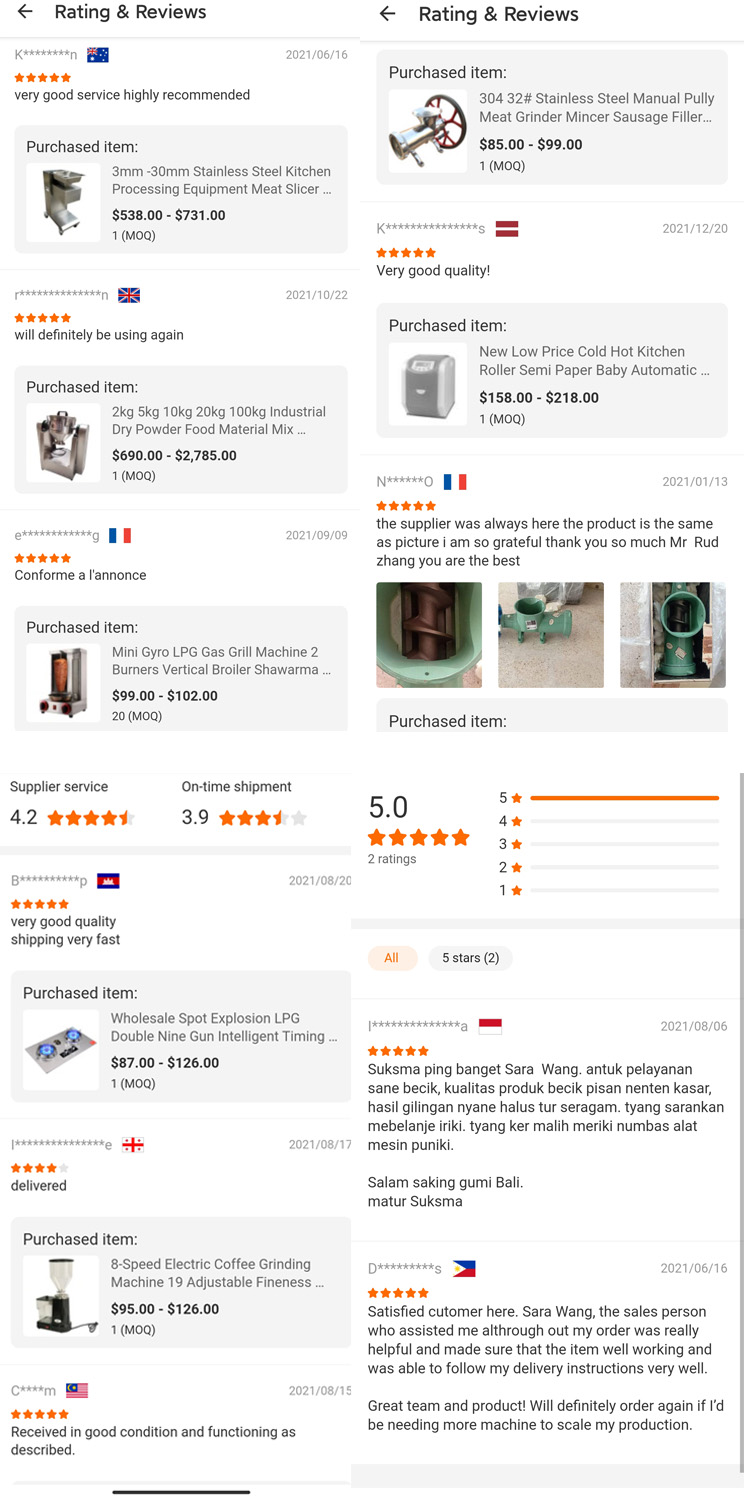

Business Type | Manufacturer | Country / Region | Henan, China |

Main Products | food machine,meat series,Bakery & dough, Refrigerator,Kitchen equipment, Chemical & Lab Machines | Employees | 50 People |

Total Annual Revenue | US$2.5 Million - US$5 Million | Established | 2001 |

Certifications | CE, CCC , ISO 9001 | Trade Marks | ISSAC MACHINE.COM |

Send your message to us

No need register, just fill in contact info below, we will reply you within 24 hours!

English

English German

German French

French Russian

Russian Spanish

Spanish Japanese

Japanese Korean

Korean Portuguese

Portuguese Ukrainian

Ukrainian Arabic

Arabic Italian

Italian