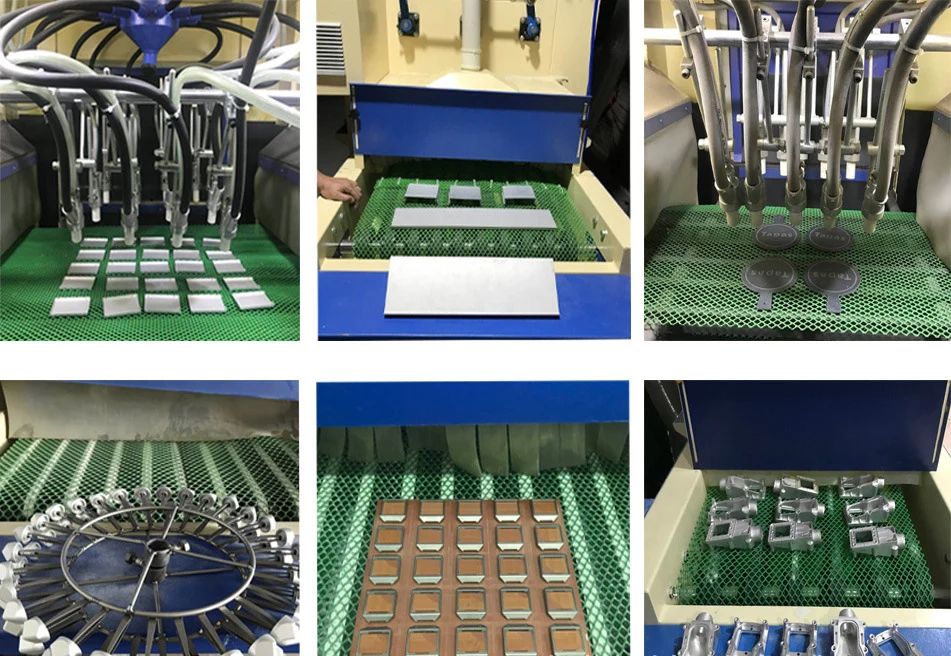

HXP-S Dry Automatic Sand Blasting Machine Plane Conveying Swing Sandblasting Operation Uniform Without Dead Angle Sand Blaster

≥1 Sets

$7,344.00

- Customized logo (Min. Order: 1 Set)

- Customized packaging (Min. Order: 1 Set)

Model Number

JC800-12A

Feature

Non-Toxic Critical Cleaning / Residue Free

Industry Used

Optics Electronic Industry

description

Specification

item | value |

Condition | New |

Machine Type | Sandblaster |

Video outgoing-inspection | Provided |

Machinery Test Report | Provided |

Marketing Type | New Product 2021 |

Warranty of core components | 1 Year |

Core Components | Motor |

Fuel | Electric |

Use | Sandblaster and Rust removing |

Cleaning Process | steel shot |

Cleaning Type | Clean-In-Place (CIP) |

Material | Metal, glass, ceramics, bamboo, wood, etc |

Power | 9000w |

Dimension(L*W*H) | 4200mm*1200mm*3000mm |

Warranty | 1 Year |

Free spare parts | |

Key Selling Points | Automatic |

After Warranty Service | Video technical support, Online support |

Applicable Industries | Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Farms, Energy & Mining |

Weight (KG) | 1200 |

Product parameters:Model: jc800-12a conveying automatic sand blasting machineMain engine shape: the main engine structure is welded with 2-10mm steel plateOverall dimension of the whole machine: 4200mm long 1200mm wide 3000mm highDimensions in the studio: 1200mm long * 1200mm wide * 1000 highDust removal box: 1200mm long * 1200mm wide * 2000 highFan power:7.5kwAutomatic conveying mechanism: 0.75KW 380V 50Hz [speed adjustable]Middle of conveying mechanism: 1220 * 3400mm is V-belt,Automatic gun holder: 0.55kw 380V 50Hz [speed adjustable]Lighting:18W fluorescent lamps*2The upper cyclone sand separation system is used for direct sand pumping sand blasting,

that is, the compressed air flows at a high speed in the spray gun to

form a negative pressure to produce the injection effect.

The sand in the cyclone separator is sucked into the spray gun through the sand conveying pipe,

and then sprayed to the workpiece surface at a high speed with the compressed air flow from the nozzle,Quantity of guns: 12 (aluminum alloy with carbonization nozzle)Doors: two, front and rear doors 800mm high * 700mm wideApplicable to: 30 mesh - 120 mesh abrasiveMaximum load capacity in the studio: 120kgTotal power: About 9kwThe air pressure is greater than 5bar (kg / cm2)

([the air compressor is more than 12m3] [the air consumption is required to be 1m3 per gun]

Product Description

characteristic:The triangular belt is used to transport the workpiece, which will not accumulate sand. The belt speed can realize variable frequency speed regulation according to the requirements of sand blasting process; The angle of each spray gun can be adjusted freely, the gun holder can realize automatic frequency conversion and swing, and fixed-point sand blasting can be carried out, with strong flexibility and wide applicability; Advanced cyclone separation system configuration is adopted, with good dust separation effect and high sand blasting efficiency; PLC advanced electrical control system is adopted, with high degree of automation, good stability and low failure rate; The nozzle is made of special high wear-resistant ceramic material with long service life; Independent bag dust removal system, good dust extraction and ventilation effect; (also optional; pulse filter element type dust removal); The abrasive recovery adopts the combination of screw conveying and pneumatic recovery, with good recovery stability.Applicable working conditions1) Environmental conditions: the machine shall work normally under the ambient temperature of - 10 ~ + 45 ℃ and the relative humidity of no more than 85%;2) Power supply conditions: single phase AC power supply, 220V, 50Hz. See attached table-3 for the maximum power of the machine;3) Air source conditions: the gauge pressure of the compressed air connected to the machine is 0.4 ~ 0.7MPa, and the compressed air flow is not less than 1m3 / min.The user site shall meet the above conditionsSand material used:Jichuan abrasives are supplied throughout the year: brown corundum sand, glass sand, silicon carbide glass, walnut sand, resin sand, emery, alumina sand, steel sand and steel shot, plastic particles (nylon sand), ceramic beads, etc.Main purpose of automatic sand blasting machine1. Cleaning and strengthening of external surface of parts;2. Cleaning and strengthening of tools, fixtures and materials;3. Surface cleaning of parts before electroplating, oxidation and coating;4. Remove pollutants on the surface of barrels, tubes, plates, cans and utensils;5. Cleaning of tools, molds, pipes, plates and operating parts;6. Surface cleaning of glass mold, rubber mold, metal casting and extrusion;7. Repair welds;8. Surface glaze of workpiece;9. Remove the oxide scale on the workpiece surface and remove the color difference during and after processing (castings and forgings);10. Clean large turbines, engine castings or complex small parts;11. Clean parts (such as cylinder block, piston and spark plug) during engine maintenance;12. Clean the surfaces of brushes, contactors and wiring technology to improve conductivity;13. Cleaning and preservation of parchment and other works of art;14. Remove the old paint and dirt on the workpiece surface.Operating proceduresAccording to the different requirements of workpiece material and processing technology, qualified sand shall be added before processing. Set the speed of the conveyor belt, the swing frequency of the spray gun, the amount of sand, the air pressure, etc. the workers only operate the control system and load and unload the workpiece, and the sandblasting on the workpiece surface is automatically completed by the machine.Start the suction and dust removal system and start the spray gun.Place the workpiece on the conveyor belt. (for small and light workpieces, the customer needs to customize the fixture)The conveyor belt conveys the workpiece into the sandblasting chamber at a uniform speed; The spray gun is driven by the swing motor to do repeated swing sand blasting to automatically sand blast the workpiece surface.After processing, the workpiece enters the blowing room (dust cover), and the internal blowing gun blows the residual sand on the workpiece surface to remove static electricity; Automatic output, just remove the product.The machine adopts continuous sand blasting.Turn off the power switch when not in use.The machine needs more than 2 operators (one for storage and one for retrieval)

Packing & Delivery

ply wooden box10-14pans -18~-24 Danfoss Compressor Countertop Gelato Counter Ice Cream Display Freezer With Stainless Steel Shutters

Company Profile

Food making machine and export to many different countries, like USA, FRANCE, Romania, Germany, Italy, and south America like Brazil, Peru. AND AFRICA.other, we can send goods free tax. we have our own clear Customs Team. we can save money for customer

FAQ

1. who are we?

We are based in Henan, China, start from 2015,sell to Africa(18.00%),Mid East(18.00%),North America(15.00%),Southeast Asia(11.00%),South America(9.00%),Western Europe(8.00%),Eastern Europe(8.00%),Southern Europe(8.00%),South Asia(3.00%),Oceania(2.00%). There are total about 11-50 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

food making machinery,ice pan machine fryer,meat grinder mixer,sausage filling machine,dumpling samosa making machine

4. why should you buy from us not from other suppliers?

Food making machine and export to many different countries, like USA, FRANCE, Romania, Germany, Italy, and south America like Brazil, Peru. AND AFRICA.other, we can send goods free tax. we have our own clear Customs Team. we can save money for customer

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,DDP,DDU,Express Delivery;

Accepted Payment Currency:USD,EUR;

Accepted Payment Type: T/T,L/C,MoneyGram,Credit Card,PayPal,Western Union,Escrow;

Language Spoken:English,Chinese,Spanish,Arabic,Russian

We are based in Henan, China, start from 2015,sell to Africa(18.00%),Mid East(18.00%),North America(15.00%),Southeast Asia(11.00%),South America(9.00%),Western Europe(8.00%),Eastern Europe(8.00%),Southern Europe(8.00%),South Asia(3.00%),Oceania(2.00%). There are total about 11-50 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

food making machinery,ice pan machine fryer,meat grinder mixer,sausage filling machine,dumpling samosa making machine

4. why should you buy from us not from other suppliers?

Food making machine and export to many different countries, like USA, FRANCE, Romania, Germany, Italy, and south America like Brazil, Peru. AND AFRICA.other, we can send goods free tax. we have our own clear Customs Team. we can save money for customer

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,DDP,DDU,Express Delivery;

Accepted Payment Currency:USD,EUR;

Accepted Payment Type: T/T,L/C,MoneyGram,Credit Card,PayPal,Western Union,Escrow;

Language Spoken:English,Chinese,Spanish,Arabic,Russian

Have more questions about this product?

Scan the QR code with your phone, or visit the URL

Have more questions about this product?

- 1-2804, Beisanhuan No. 52, Zhengzhou, China

- whatsapp: +86 17329438411

- rodzhang@issacmachine.com